Table of Contents

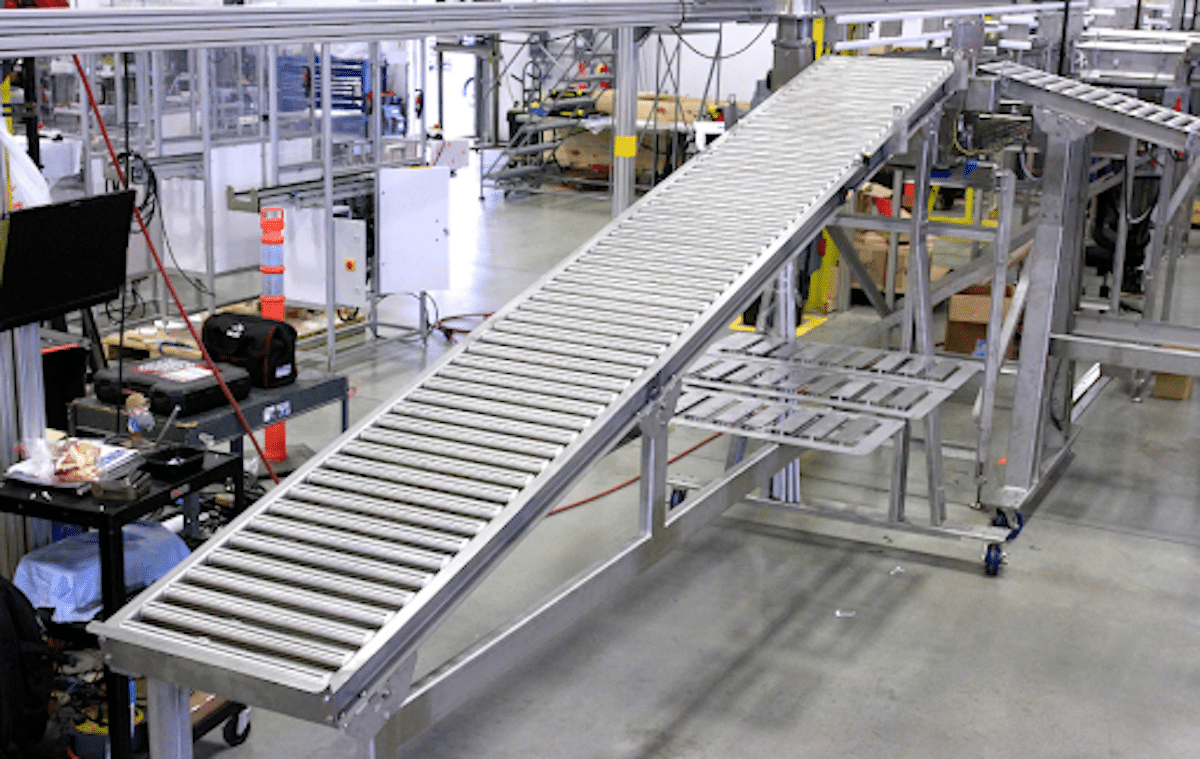

Roller conveyors are mechanical systems that move materials or goods from one location to another using rollers. They are one of the most common types of conveyor systems and are used in a wide range of industries, including manufacturing, distribution, warehousing, and food and beverage. Conveyors Mexico is a leading supplier of conveyor systems in Mexico, offering a wide range of conveyor types and configurations to meet the needs of various industries. In this article, we will discuss what roller conveyors are and the types of roller conveyors that are available in the market.

Types of Roller Conveyors

There are four main types of roller conveyors available: gravity roller conveyors, powered roller conveyors, chain-driven roller conveyors, and belt-driven roller conveyors.

Gravity Roller Conveyors

Gravity roller conveyors are the simplest type of roller conveyor. They work by using the force of gravity to move materials or goods along the conveyor line. Gravity roller conveyors have no external power source and rely solely on the slope of the conveyor and the force of gravity to move items. They are typically used for moving lightweight materials or goods, such as boxes or bags.

How Gravity Roller Conveyors Work

Gravity roller conveyors have a sloping surface that is angled downward in the direction of movement. The rollers on the conveyor line are spaced out and positioned perpendicular to the slope of the conveyor line. When an item is placed on the conveyor, the force of gravity pulls it down the slope of the conveyor and along the conveyor line.

Advantages of Gravity Roller Conveyors

Gravity roller conveyors have several advantages, including:

- Low Cost: Gravity roller conveyors are relatively inexpensive compared to other types of roller conveyors.

- Low Maintenance: Since they have no external power source, gravity roller conveyors are low maintenance and require minimal upkeep.

- Versatility: Gravity roller conveyors can be used for a wide range of applications, from transporting boxes and bags to small parts.

Disadvantages of Gravity Roller Conveyors

Gravity roller conveyors also have some disadvantages, including:

- Limited Capacity: Gravity roller conveyors are not suitable for transporting heavy items.

- Inconsistent Speed: The speed of gravity roller conveyors depends on the slope of the conveyor and the weight of the item being transported. This can make it difficult to maintain a consistent speed along the entire conveyor line.

- Limited Control: Since gravity roller conveyors have no external power source, they offer limited control over the movement of items along the conveyor line.

Powered Roller Conveyors

Powered roller conveyors are conveyor systems that use external power sources, such as motors, to move items along the conveyor line. They are typically used for transporting heavy materials or goods over long distances.

How Powered Roller Conveyors Work

Powered roller conveyors have one or more motors that provide the external power needed to move items along the conveyor line. The motors are connected to the rollers, which are positioned along the conveyor line. The speed of the conveyor can be adjusted using the motor controls, allowing for greater control over the movement of items along the conveyor line.

Advantages of Powered Roller Conveyors

Powered roller conveyors offer several advantages, including:

- High Capacity: Powered roller conveyors are capable of transporting heavy items over long distances.

- Consistent Speed: Since the speed of powered roller conveyors can be adjusted using the motor controls, they offer a consistent speed along the entire conveyor line.

- Control: Powered roller conveyors offer greater control over the movement of items along the conveyor line, allowing for greater precision and accuracy.

Disadvantages of Powered Roller Conveyors

Powered roller conveyors also have some disadvantages, including:

- High Cost: Powered roller conveyors are more expensive than gravity roller conveyors.

- Maintenance: Since they have external power sources, powered roller conveyors require more maintenance than gravity roller conveyors.

- Complexity: Powered roller conveyors are more complex than gravity roller conveyors, which can make them more difficult to install and operate.

Chain Driven Roller Conveyors

Chain-driven roller conveyors are conveyor systems that use chains to move items along the conveyor line. They are typically used for transporting heavy materials or goods over long distances.

How Chain-Driven Roller Conveyors Work

Chain-driven roller conveyors have a series of chains that are connected to the rollers along the conveyor line. The chains are driven by an external power source, such as a motor, which provides the force needed to move items along the conveyor line.

Advantages of Chain-Driven Roller Conveyors

Chain-driven roller conveyors offer several advantages, including:

- High Capacity: Chain-driven roller conveyors are capable of transporting heavy items over long distances.

- Consistent Speed: Since the speed of chain-driven roller conveyors can be adjusted using the motor controls, they offer a consistent speed along the entire conveyor line.

- Control: Chain-driven roller conveyors offer greater control over the movement of items along the conveyor line, allowing for greater precision and accuracy.

Disadvantages of Chain-Driven Roller Conveyors

Chain-driven roller conveyors also have some disadvantages, including:

- High Cost: Chain-driven roller conveyors are more expensive than gravity roller conveyors.

- Maintenance: Since they have external power sources, chain-driven roller conveyors require more maintenance than gravity roller conveyors.

- Complexity: Chain-driven roller conveyors are more complex than gravity roller conveyors, which can make them more difficult to install and operate.

Belt Driven Roller Conveyors

Belt-driven roller conveyors are conveyor systems that use belts to move items along the conveyor line. They are typically used for transporting heavy materials or goods over long distances.

How Belt-Driven Roller Conveyors Work

Belt-driven roller conveyors have a series of belts that are connected to the rollers along the conveyor line. The belts are driven by an external power source, such as a motor, which provides the force needed to move items along the conveyor line.

Advantages of Belt-Driven Roller Conveyors

Belt-driven roller conveyors offer several advantages, including:

- High Capacity: Belt-driven roller conveyors are capable of transporting heavy items over long distances.

- Consistent Speed: Since the speed of belt-driven roller conveyors can be adjusted using the motor controls, they offer a consistent speed along the entire conveyor line.

- Control: Belt-driven roller conveyors offer greater control over the movement of items along the conveyor line, allowing for greater precision and accuracy.

Disadvantages of Belt-Driven Roller Conveyors

Belt-driven roller conveyors also have some disadvantages, including:

- High Cost: Belt-driven roller conveyors are more expensive than gravity roller conveyors.

- Maintenance: Since they have external power sources, belt-driven roller conveyors require more maintenance than gravity roller conveyors.

- Complexity: Belt-driven roller conveyors are more complex than gravity roller conveyors, which can make them more difficult to install and operate.

Conclusion

Roller conveyors are a versatile and efficient type of conveyor system that is used in a wide range of industries and applications. There are several different types of roller conveyors, including gravity roller conveyors, powered roller conveyors, chain-driven roller conveyors, and belt-driven roller conveyors. Each type of conveyor offers its own unique advantages and disadvantages, depending on the specific needs of the application.

Frequently Asked Questions

What are roller conveyors used for?

Roller conveyors are used for transporting materials or goods along a conveyor line.

What are the different types of roller conveyors?

The different types of roller conveyors include gravity roller conveyors, powered roller conveyors, chain-driven roller conveyors, and belt-driven roller conveyors.

What are the advantages of gravity roller conveyors?

The advantages of gravity roller conveyors include low cost, simplicity, and ease of use.

What are the advantages of powered roller conveyors?

The advantages of powered roller conveyors include high capacity, consistent speed, and greater control.

What are the disadvantages of chain-driven roller conveyors?

The disadvantages of chain-driven roller conveyors include high cost, maintenance, and complexity.