Table of Contents

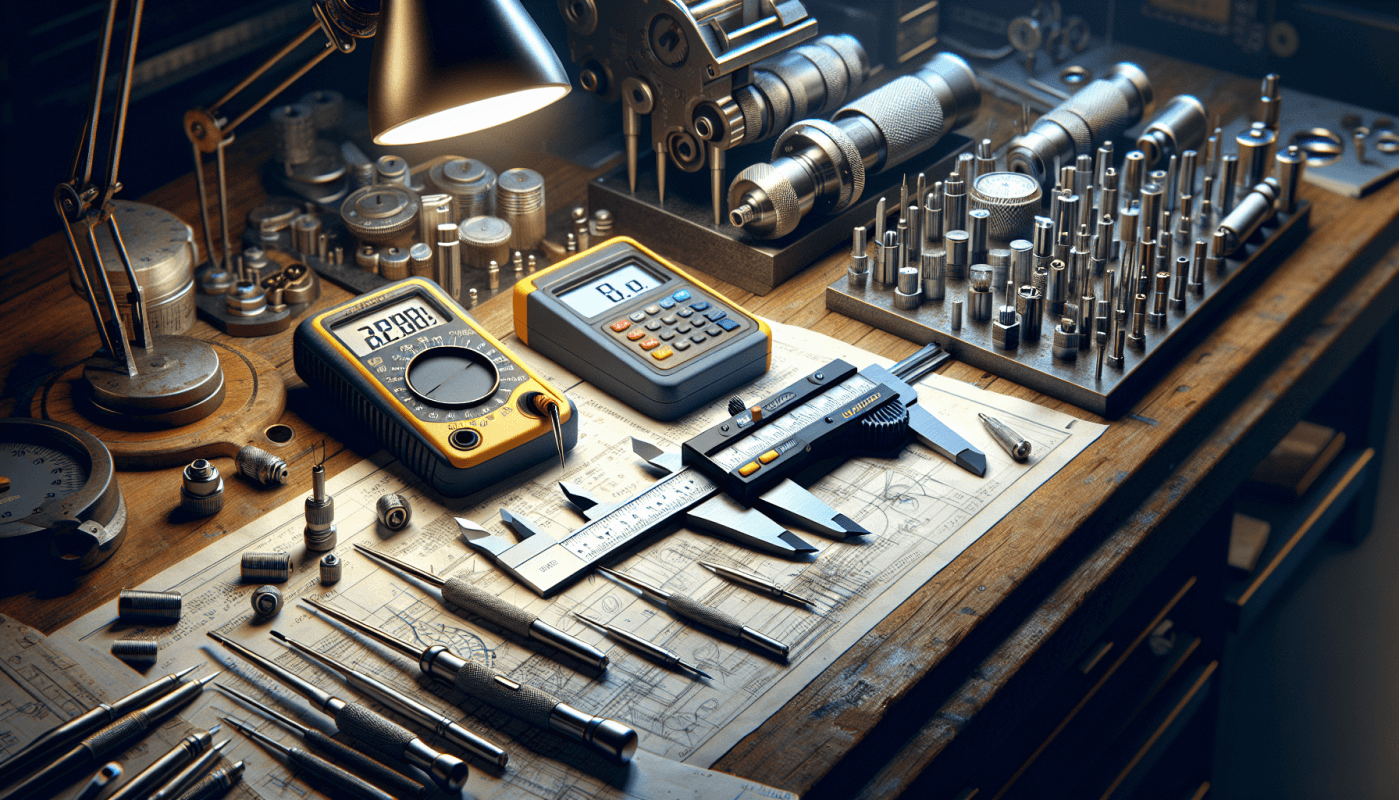

Accurate measurements hold importance across industries ranging from manufacturing to engineering. When it comes to achieving consistent results in precision measurement, metrology tools play a role. This guide will delve into the arsenal of metrology tools that professionals can rely on for precise measurements. Whether you are involved in construction, automotive, aerospace or any other industry where precision is critical, this guide offers insights into selecting the appropriate tools for your specific needs.

I. Calipers: Measuring Distances and Thicknesses

Measuring distances and thicknesses is fundamental in every field that deals with objects. Callipers serve as measuring instruments with applications ranging from mechanics and metalworking to healthcare industries. Callipers are one of the most essential metrology tools that eliminate guesswork and ensure utmost accuracy by providing measurements of external dimensions.

While traditional vernier callipers have long been trusted in workshops due to their reliability, digital callipers have gained popularity owing to their user-friendliness and high level of precision.

II. Micrometers: Ensuring Measurements with Reliability

Professionals turn to micrometres as their go-to tool when it comes to precise linear measurements at the micrometer or sub-micrometer level. The distinct advantage of micrometres lies in their capability to accurately measure dimensions that may be beyond the reach of callipers.

External micrometres are widely utilised to achieve measurements of diameters in machining operations. In contrast, internal micrometers enable technicians to obtain accurate readings of internal dimensions like bore diameters or groove widths. Having an understanding of these types allows professionals to make informed decisions based on the specific measurement requirements dictated by different tasks.

III. Laser Measurement Tools: Embracing Non-Contact Accuracy

In situations where contact-based measurement may not be feasible due to the properties of materials or the delicacy of surfaces being measured, laser measurement tools offer a solution. Laser distance meters provide precise measurements, eliminating errors that may arise from estimating with a tape measure or similar tools.

These non-contact measurement solutions find applications in fields such as architecture, interior design, building inspection and civil engineering. The ability to capture measurements without contact ensures higher efficiency and time savings.

IV. Dial Indicators: Measuring Precise Shifts and Alignments

Professionals across industries rely on dial indicators when dealing with relative position measurements or detecting the slightest movement or deflection in mechanical systems. These mechanical tools allow technicians to identify minute shifts that go beyond the detection limit of measuring devices.

Including dial indicators in your toolbox enhances precision when aligning machine parts, conducting inspections on assemblies or tuning parameters in a production setup.

V. Advanced Metrology Solutions for Precision Manufacturing: Coordinate Measuring Machines (CMM)

Coordinate measuring machines (CMMs) offer solutions in metrology by combining hardware and software capabilities to analyse measurements comprehensively. CMMs excel at measuring objects in three-dimensional space, ensuring that manufacturing quality control processes meet high standards.

The exceptional accuracy and repeatability of CMMs make them indispensable across industries where superior quality assurance is crucial. Converting dimensions into data CMMs enables extensive statistical analysis while facilitating the creation of 3D models for further evaluation.

VI. Evaluating Surface Textures and Quality: Surface Roughness Testers

Surface roughness testers are instruments used in industries that require the evaluation of surface finishes and textures. These tools provide measurements to assess surface quality, roughness and smoothness.

Professionals rely on surface roughness testers to determine the suitability of surfaces for applications, identify imperfections or irregularities that may impact performance and ensure compliance with industry standards. Parameters such as Ra ( roughness), Rz ( peak to valley height) and Rt (total roughness) are measured by these devices, offering a comprehensive understanding of surface texture.

Conclusion:

As a carpenter or craftsman relies on their well-stocked toolbox, professionals in industries that require precise measurements must have the right metrology tools. From callipers to coordinate measuring machines (CMM), each tool serves specific purposes at different levels of complexity and accuracy.

By understanding these metrology tools, you can make decisions about which ones are best suited for your industry’s specific needs. Ensuring that your toolkit includes the selection of instruments will ensure accurate measurements and maintain a high standard of quality in your work. Remember, having the right tools available is often the step towards consistently achieving excellent results.