Table of Contents

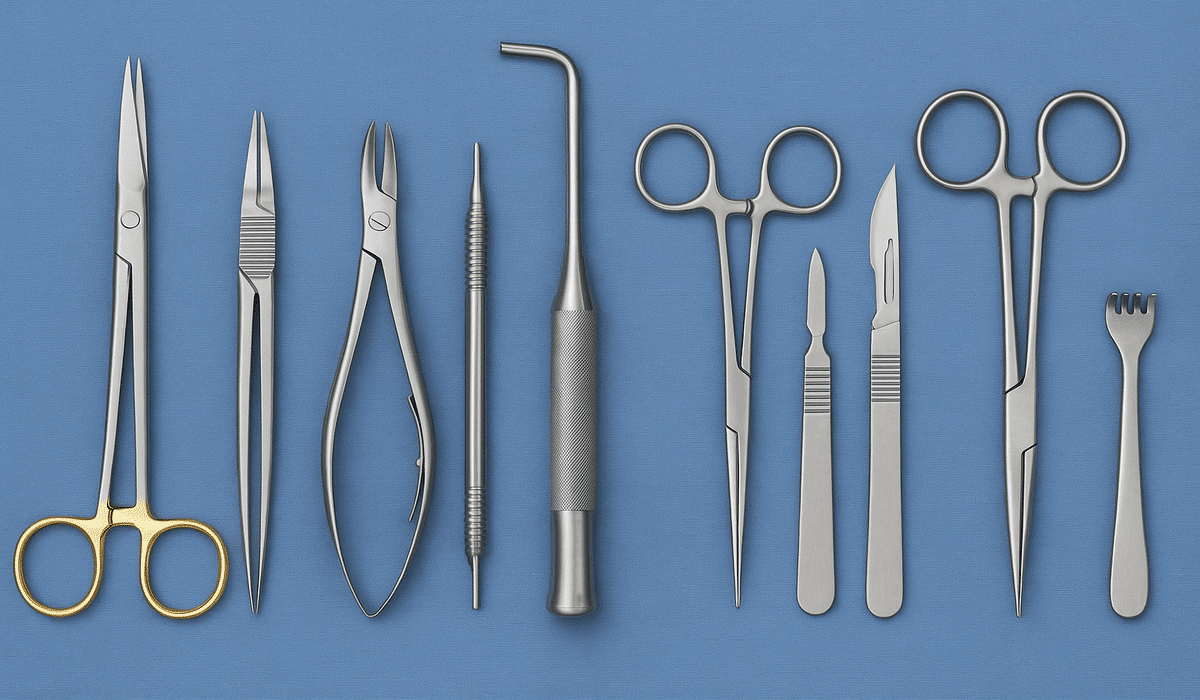

In the high-stakes world of healthcare, precision and reliability are non-negotiable. Whether performing a complex surgery or a routine procedure, medical professionals rely heavily on the tools in their hands. However, even the finest surgical instruments will fail if they are not properly cared for.

Proper maintenance doesn’t just preserve the life of your tools—it protects your patients and ensures consistent clinical outcomes. Partnering with a trusted medical instrument supplier like Sklar Instruments is the first step, but long-term performance hinges equally on how those instruments are handled post-purchase.

In this guide, we’ll walk through everything healthcare providers need to know about surgical instrument care, ensuring safety, efficiency, and value for years to come.

1. Understanding Surgical Instrument Materials

Not all surgical instruments are created equal.

Different materials react differently to cleaning agents, sterilization processes, and general wear and tear.

Stainless Steel:

The industry standard. High-grade stainless steel, especially German or U.S. steel, offers excellent corrosion resistance and durability when properly cared for.

Titanium:

Lighter and stronger than steel. Titanium instruments are ideal for delicate procedures and are highly resistant to corrosion but require specialized cleaning techniques.

Disposable Instruments:

Made from lower-grade materials intended for single-use. While convenient, they lack the precision and longevity of premium instruments.

Choosing instruments from a reputable medical instrument supplier ensures that you’re starting with high-quality materials designed for rigorous healthcare environments. Companies like Sklar Instruments, for example, provide OR-Grade surgical tools engineered for maximum durability.

2. Best Practices for Cleaning Surgical Instruments

Cleaning is the first and most important step in preserving surgical instruments. Immediate and thorough cleaning after every use prevents blood, proteins, and other contaminants from hardening and causing corrosion.

Recommended Steps:

Pre-Clean Immediately:

Wipe down instruments with a sterile, damp cloth immediately after use to prevent drying of organic material.

Manual Cleaning:

Use a soft brush and pH-neutral enzymatic detergent. Pay special attention to hinges, serrations, and crevices.

Avoid Harsh Chemicals:

Bleach, strong acids, or saline can corrode surgical steel. Only approved cleaners should be used.

Rinse Thoroughly:

After cleaning, rinse with distilled water to prevent mineral deposits.

Common Mistakes to Avoid:

- Letting debris dry on instruments.

- Using abrasive scrubbers that scratch surfaces.

- Skipping drying after rinsing.

Proper cleaning, combined with purchasing from a trusted medical instrument supplier, significantly reduces the risk of surgical site infections and extends the life of your tools.

3. Importance of Sterilization and Correct Methods

Once cleaned, instruments must be sterilized to eliminate microbial threats. Different instruments require different sterilization protocols.

Key Sterilization Methods:

Autoclaving (Steam Sterilization):

Most commonly used for surgical steel instruments. Ensure instruments are open (not locked) and not overcrowded.

Chemical Sterilization:

For heat-sensitive tools. Use solutions approved for medical-grade equipment.

Ultrasonic Cleaning:

Uses high-frequency sound waves to remove debris from hard-to-reach areas before sterilization.

Critical Points to Remember:

- Always fully dry instruments before sterilization.

- Separate delicate instruments from heavy ones to avoid damage.

- Use validated sterilization cycles recommended by the manufacturer.

Following best practices ensures that the investment made with your medical instrument supplier continues to pay off in clinical reliability.

4. Inspection and Routine Maintenance

Even with the best cleaning practices, surgical instruments require regular inspection and maintenance.

Inspection Checklist:

- Check for cracks, warping, corrosion, or misalignment.

- Ensure scissors are sharp and cut cleanly through test materials.

- Verify that hinges and joints move smoothly.

Routine Maintenance:

- Lubricate moving parts with medical-grade instrument lubricant (“milk baths”).

- Sharpen blades and adjust tension as necessary.

- Retire or professionally refurbish instruments that fail inspection.

Partnering with a medical instrument supplier who offers repair and maintenance services—like Sklar Instruments—can help extend the life of your surgical inventory even further.

5. Proper Storage and Handling

Storage is often an overlooked component of instrument care, but it’s essential for maintaining integrity and performance.

Best Storage Practices:

- Store instruments dry and at room temperature to prevent rust and pitting.

- Use instrument trays with silicone mounts to protect delicate tips and joints.

- Organize instruments by size and specialty to reduce handling damage.

Handling Tips:

- Always transport instruments carefully in protective cases.

- Avoid stacking heavy instruments on top of delicate ones.

- Train staff on correct handling procedures to minimize accidents.

Proper storage not only protects the instruments but also ensures readiness when patient care demands speed and precision.

6. Why Choosing the Right Medical Instrument Supplier Matters

Even the best maintenance routines cannot compensate for poor-quality instruments.

Choosing a reputable, established medical instrument supplier ensures:

- Access to high-quality, durable surgical tools.

- Reliable customer support for warranties, repairs, and education.

- Compliance with international healthcare and safety standards.

Sklar Instruments, for example, has been a trusted name in surgical tools for over 130 years, offering healthcare providers peace of mind that their instruments are crafted for excellence and longevity.

Investing in premium instruments from a trusted supplier, and then properly maintaining them, is the key to long-term value, operational efficiency, and—most importantly—exceptional patient care.

Conclusion

Surgical instruments are more than tools—they’re critical to the success of every procedure and the safety of every patient.

Proper care, routine maintenance, and careful handling dramatically extend the life and performance of your instruments.

But it all starts with choosing a reliable medical instrument supplier that offers the highest standards of quality, service, and support.

When precision, safety, and trust are on the line, every detail matters—especially the instruments in your hands.