Whether you are installing a new LED light strip or just cutting off a part of the LED strip, you need to know how to cut the LED lights without breaking them. You can do this by using a specialized tool called a “strip cutter.”

Can you cut LED light strips without breaking them?

How to cut LED light strips is not complicated, but there are a few things you should know before cutting the lights. This will ensure that you do not break them and that the lights will work properly. For more knowledge, you can also Google “superlightingled” to get online technical support

First, you should determine the length of the LED light strip. This is important because you do not want to cut it too far and end up with a flimsy light. You also need to check whether the light will work after you cut it.

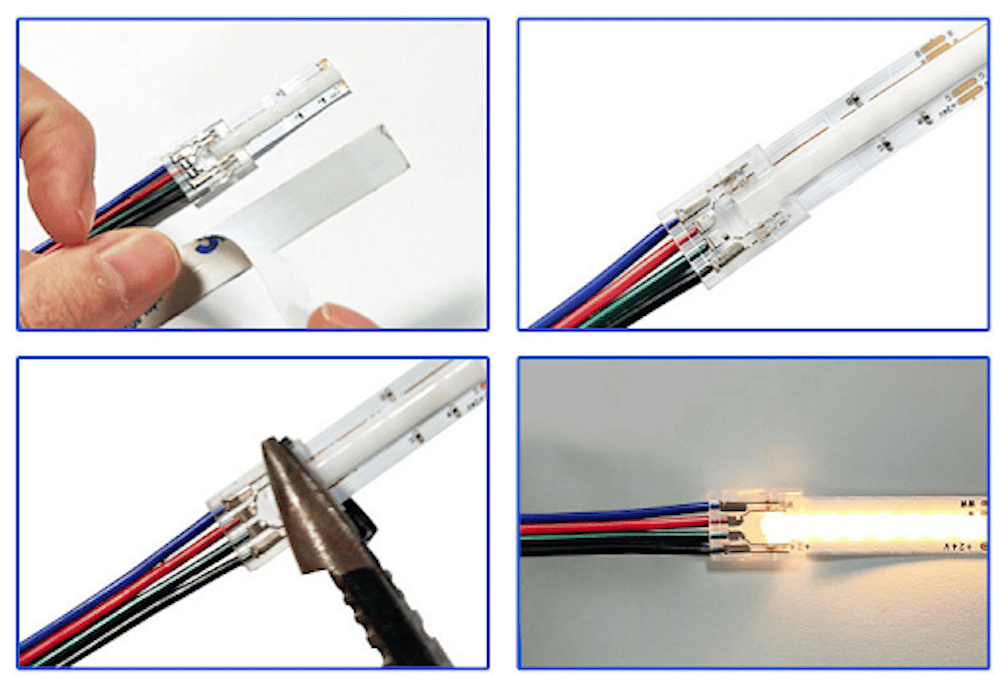

If the LED lights aren’t working after you’ve cut them, you may have made a mistake. If you don’t, you can fix the problem by reconnecting the LEDs with an additional 4-pin connector. This will make the connection stronger and more secure.

Before cutting the LED strip, you should make sure that the copper pads are exposed. This is because the light will only work if it is cut at the right places. You should also look for a scissor icon, which is a small, scissor-like icon that is placed along the suitable sections of the LED strip.

Once you have decided on the cut point, you can use a pair of scissors to cut the LED light strip. It should be noted that you should never cut the LED lights when they are connected to a power source. This is because you risk damaging the circuits.

Properly connect LED strip lights to a power supply

Whether you are planning to customize your LED light strips or just want to cut them into a specific length, it is important to properly connect them to a power supply before cutting them. Otherwise, you will damage the lights and the strip will not work.

LED light strips are constructed with two copper layers, which are separated by a thin layer of insulation. In order to cut the strip, you must carefully follow the cut lines. If you cut outside the cut lines, you will damage the entire strip. This will also kill the individual circuits.

The cut line on the LED light strip is indicated by copper dots. You must carefully cut through the dots to get a clean cut. If you cut outside the copper dots, you will not cut through the insulating layer and the circuit will stop working. The cut lines are usually every three LEDs. You can use a sharp knife to cut through the plastic. If the LED strip is a little dense, you may have to cut it into smaller pieces.

You must also make sure the wires are connected securely. You must match the terminals on the LED with the terminals on the wires. It is a good idea to have a soldering iron at hand, especially if you are making multiple connections.

Cutting LED light strips into usable pieces

Getting your LED lights to work properly is easy if you cut them correctly. The first thing to do is to make sure you’re cutting the strip at the right length.

The easiest way to cut a LED strip is to use a pair of scissors. However, this method can cause the light to stop working. This is because the cut will not be in the proper place, which can damage the LEDs. The best way to cut a strip is to follow the instructions.

Once you’ve cut the strip, it’s important to make sure the wires are soldered to the strip. The wires must match up with the terminals on the LEDs. If you don’t do this, the lights will not work.

In addition to ensuring the length is correct, you must also ensure that the polarity of the wires is correct. This is because the polarity will affect the way electricity passes through the circuit. If the polarity is wrong, the LEDs won’t light up.

Once you’ve cut the LED strip, you must reconnect the lights to the power source. There are two ways to do this. You can either use a quick connector or soldering. Both methods require a lot of work, so if you want to save time, you can use the quick connector. If you want to use soldering, you’ll need an iron.