Table of Contents

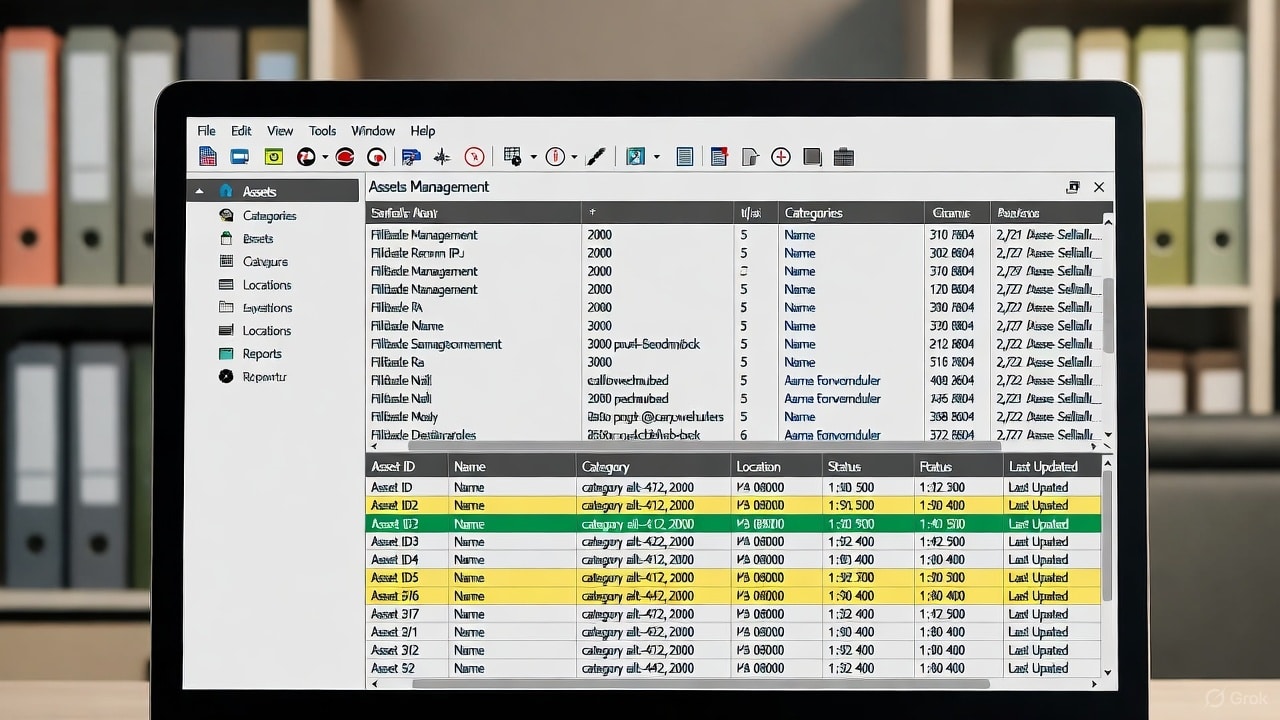

With all the new gadgets and software around, companies need to keep their machinery, vehicles, and even digital tools running perfectly. That’s how they keep expenses low and their teams highly productive. Imagine how much smoother your maintenance runs would be when asset software gives you one spot to track, handle, and improve every piece of equipment.

Modern asset management softwares really upgrades how we do maintenance. They give us useful, working solutions that transform traditional reactive approaches into proactive strategies. Let’s explore the specific ways these tools can revolutionize your maintenance operations.

Improving Asset Tracking

Effective asset tracking is the foundation of any sound maintenance strategy. This software tracks your gear. It shows its spot, use, and condition. Offering an immediate, transparent view of all corporate holdings, this method considerably lessens the possibility of operational setbacks from lost or misfiled materials. When companies get solid facts fast, they can smartly decide how to use their equipment and when to fix it.

Enhancing Preventive Maintenance

Preventive maintenance is essential to prolong the lifespan of assets and prevent unexpected breakdowns. With asset management software, setting up routine maintenance is simple. That way, tasks happen exactly when they’re needed. Imagine never missing a scheduled inspection. Automatic alerts and reminders make sure your maintenance staff stays ahead, stopping machines from failing when you least expect it. Acting early stops issues before they grow, keeping things running and cutting expenses.

Improving Resource Allocation

Allocating resources well is vital for a smooth maintenance operation. Asset management software assists in identifying which assets need attention and when. If you line up maintenance work based on how critical and pressing it is, your business can spend its money and labor much smarter. You get more done with less fuss. So, our maintenance folks handle a steady workload, meaning every piece of vital gear gets the thorough check-ups it truly needs.

Facilitating Data-Driven Decisions

Making informed decisions is easier with access to accurate and up-to-date data. Asset management software shows you exactly how well your equipment runs, what work has been done on it, and how much money it takes to keep things going. When businesses look at their information, they can easily find common habits or changes. This helps them plan better for all their equipment care. Facts show the way. Businesses make better plans, improving their work.

Improving Compliance and Safety

Compliance with industry standards and safety regulations is a priority for any organization. Asset management tools keep track of all your equipment. This way, you can easily prove everything follows the rules, thanks to complete records of every check and repair. According to the Occupational Safety and Health Administration, companies that maintain comprehensive equipment records experience 40% fewer safety incidents compared to those with manual tracking systems. Imagine an audit: these papers prove you’ve got safety down pat. They keep everyone safer and steer you clear of costly legal messes.

Reducing Costs and Increasing Performance

One of the primary benefits of asset management software is cost reduction. Planning your equipment fixes better and using company assets more smartly really brings down the day-to-day costs of running a business. Predictive maintenance catches trouble early. That stops minor glitches from turning into major, wallet-draining repairs down the road. Smart use of your resources and keeping things running smoothly really helps operations hum along.

Enhancing Communication and Collaboration

Effective communication and collaboration among maintenance teams are crucial for smooth operations. This software gives your whole team a single spot to work from. Everyone can easily share updates, check progress, and chat instantly with each other. When individuals contribute cohesively and share a common understanding, challenges are overcome with greater speed, elevating overall output.

Simplifying Inventory Management

Managing spare parts and inventory is a critical aspect of maintenance. No more guessing about stock; asset software actively monitors quantities and triggers instant alerts when supplies run low, preventing shortages. This removes the worry of stockouts completely. Vital parts are consistently available, precisely when they’re required for operational continuity. Good inventory control cuts down repair waits. It helps all maintenance work run without a hitch.

Enabling Scalability and Flexibility

As businesses grow, their maintenance needs evolve. Asset management software is scalable and can accommodate the changing demands of an organization. You’re growing, you’re adding new parts, and this software just keeps pace. It changes to fit exactly what your business requires. Because it’s so flexible, your maintenance plans stay reliable through all your company’s growth or shifting priorities.

Conclusion

Imagine smarter equipment care; this software totally changes your maintenance approach. It makes following progress simple and improves how we stop issues before they grow. Then, with solid information guiding choices, the benefits multiply greatly. Smart use of resources, following all the rules, and clear communication really help make it work well. Want to get your maintenance operations running smoother and trim those expenses? Asset management software offers a big advantage. It works well and changes on the fly. You get the right help to keep your stuff in top shape, leading to lasting good results.