Table of Contents

Key takeaways

A good design of a SCADA system can help you stretch to get more energy / revenue from the same solar assets.

Real-time monitoring and control reduces downtime, truck rolls, and guesswork to your operations team.

Smart control strategies ensure that you stay on the right end of utility and grid requirements.

The selection of your partner for the design, integration, and support of a solution determines performance for the life of the project.

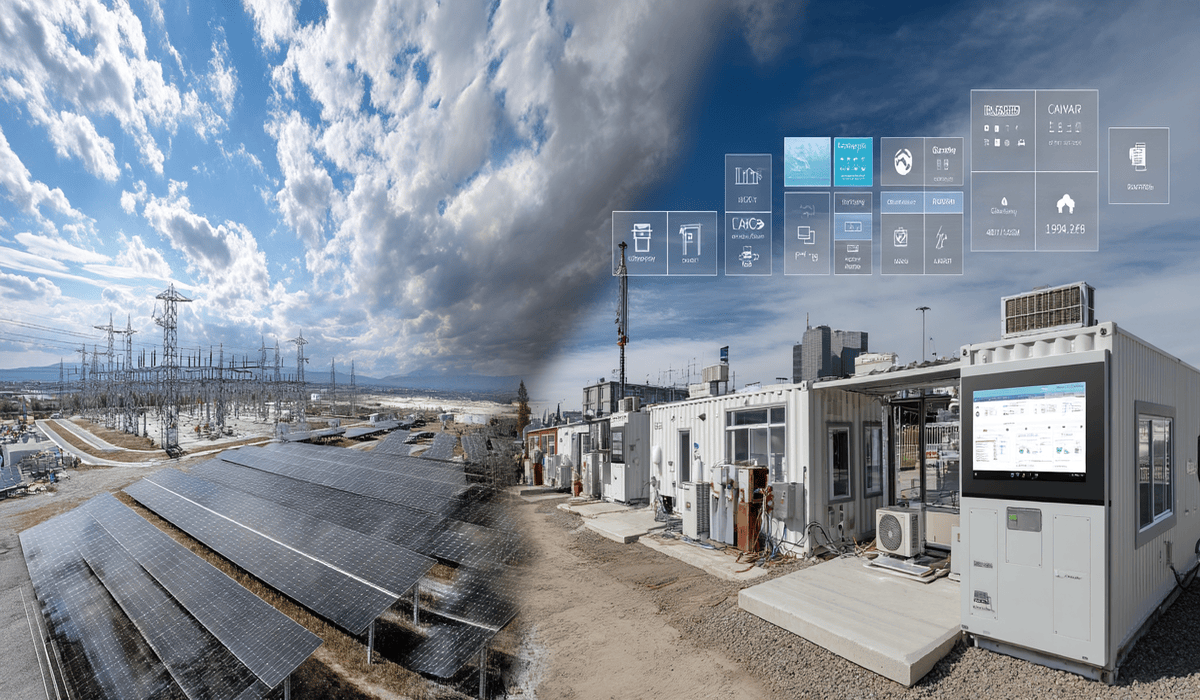

Role of SCADA and Smart Controls in Solar Optimization

If you are the owner or manager of a solar power plant, then you know that the hardware is only half the story.

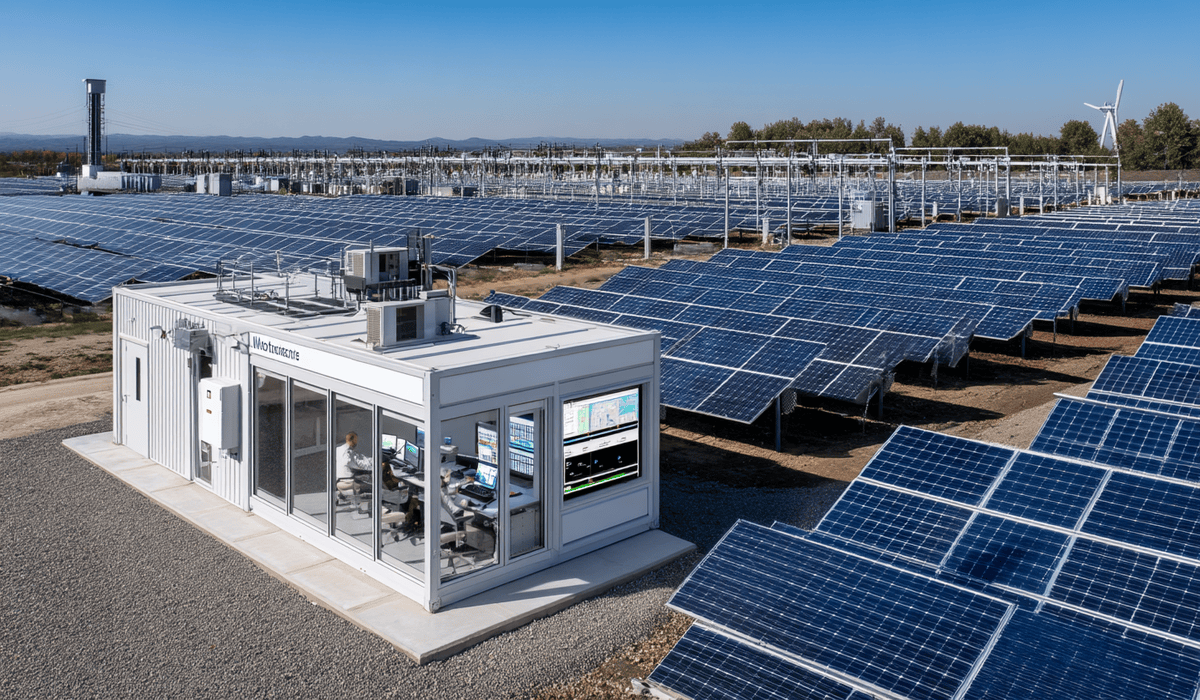

The other half is in the control room. A SCADA system, short for supervisory control and data acquisition, is the connection of your inverters, meters, trackers, and sensor that allows your operator to see what is happening so that they are able to act quickly.

I recall going on a solar farm where there was a tripped feeder on a Saturday. Before SCADA, they would know Monday. With the real-time monitoring, the operator was not only able to see the alarm, they were able to remote reset the alarm and get the power output back on within minutes.

That one incident paid for a chunk of their monitoring system.

You would like to have that kind of control and not just pretty dashboards.

SCADA for Solar PV Plants Basics

In the case of a solar pv plant, the SCADA system connects various field devices, communication networks, and a central control center. You have remote terminal unit panels or PLCs located in the field, a scada server and historian located in the control room, and then an HMI in which your operator works.

A typical utility pv plant can contain tens of thousands of tags, inverter status, string currents, breaker positions, weather status, and so on.

In one project I worked on, we did a before and after comparison between uptime before and after using scada software. After their upgrade, average response time to critical alarms was reduced from 45 minutes to below 10. That translated into quite measurable energy production gains over the year.

The National Renewable Energy Laboratory‘s report regarding solar PV plant monitoring and control using SCADA illustrates the detail of inverter and string-level information used to directly enhance availability and energy yield. In that study, NREL points to the use of properly implemented SCADA architectures to achieve faster detection and resolution of faults within extensive utility scale sites.

So even the basic architecture matters more than people think of.

Importance of a Solar SCADA and Smart Control System

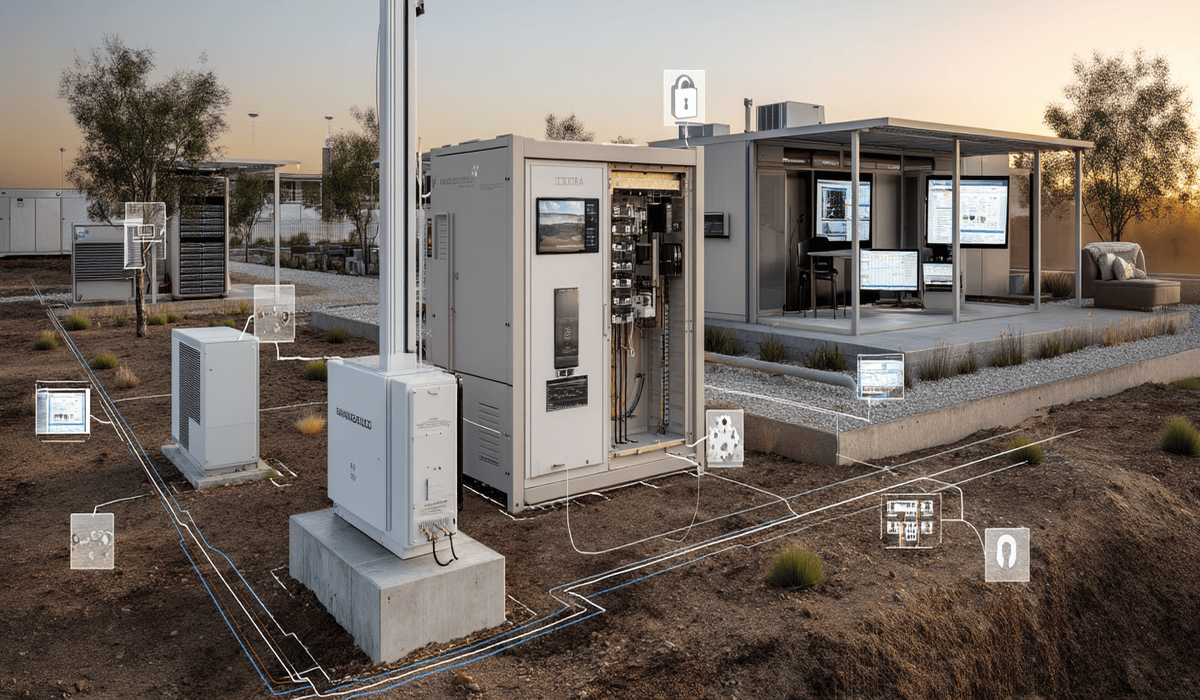

At the field level, you have inverters, combiner blocks, trackers, meters, relays and every sensor feed-backing data. Accurate irradiance and temperature measurement help you compare expected vs. actual power production and identify problems early.

Those signals are transmitted down fiber, copper or wireless networks using protocols such as Modbus or DNP3. Poor design here translates to noise, latency and dropping data. I have seen plants where a single unmanaged switch caused random communication failures through peak heat.

In the control center, the historian is used for the collection of collected data, and the HMI allows the operator to monitor and control equipment. A 50 MW solar plant can generate gigabytes of data collections on a daily basis.

In one warranty dispute, long term historian records showed an inverter underperforming the day it was installed and this helped to save the owner millions of real money.

Ways in which SCADA and Smart Controls Improves Solar Performance

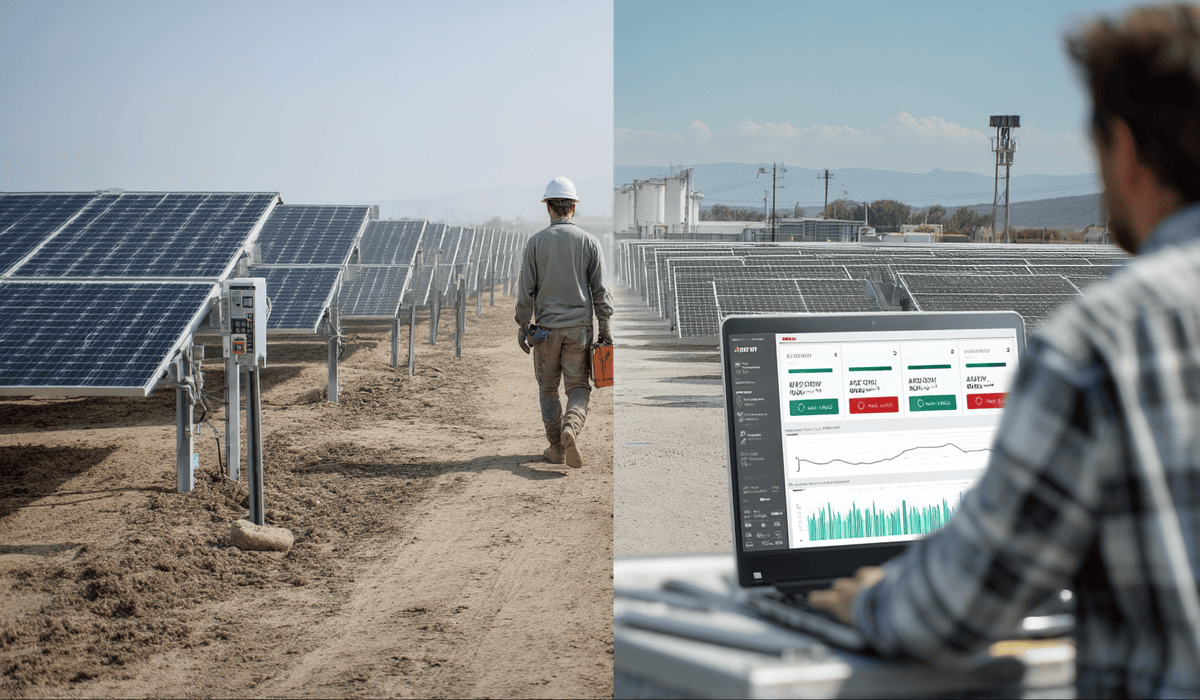

The most obvious benefit is the reduction of downtime. With live time data and alarms your operator can identify which feeder, string or inverter went bad instead of guessing. Remote commands could be the answer that often restores service without the need for a truck roll.

On one site, a SCADA upgrade reduced mean time to repair by approximately 30 percent. That is not a small number when every hour off the grid is revenue lost.

Smart control systems also play a part in the optimization of energy yield. You can track the performance ratio, detect soiling and see when a tracker row is stuck. I have certainly seen the losing a few percent of power output every sunny day that some misconfigured MPPT group hasn’t worked. It was caught by a SCADA trend analysis.

Ask yourself: are you scheduling operation and maintenance by habit, or by the data that your operations data is showing?

Smart Controls for Different Traders of Solar Projects

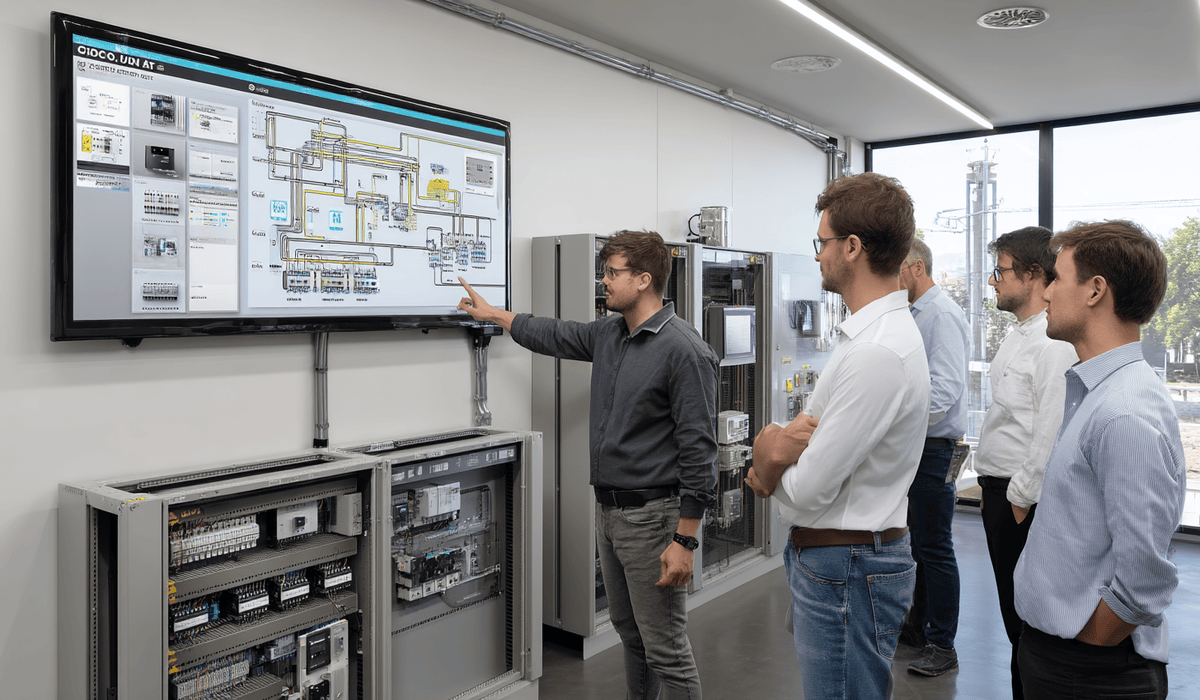

Utility-scale solar power plant projects typically have complex grid needs and are large tag projects. The SCADA system must talk to the utility or ISO, send telemetry and do what they are told as dispatch orders or curtailment. I have seen operators manage reactive power and ramp rates directly from the HMI in times of stressed grid situation.

Commercial uses of solar installations on rooftops or carports are smaller in appearance, but have different control challenges. You have to deal with tariffs, demand charges and building loads. In one C&I site, smarter controls to coordinate inverter output with HVAC schedules reduced peak demand by double digits and paid back in a few years.

Add-in storage and the picture becomes different. SCADA must coordinate with the EMS or BMS for scheduling the charge and discharge, backup loads and smoothing the pv fluctuations. Microgrids and remote locations take this to another level, where control logic makes the determination of what loads, if any, will remain on when the grid is absent.

Data, Analytics, Reporting for Storing Solar Optimization

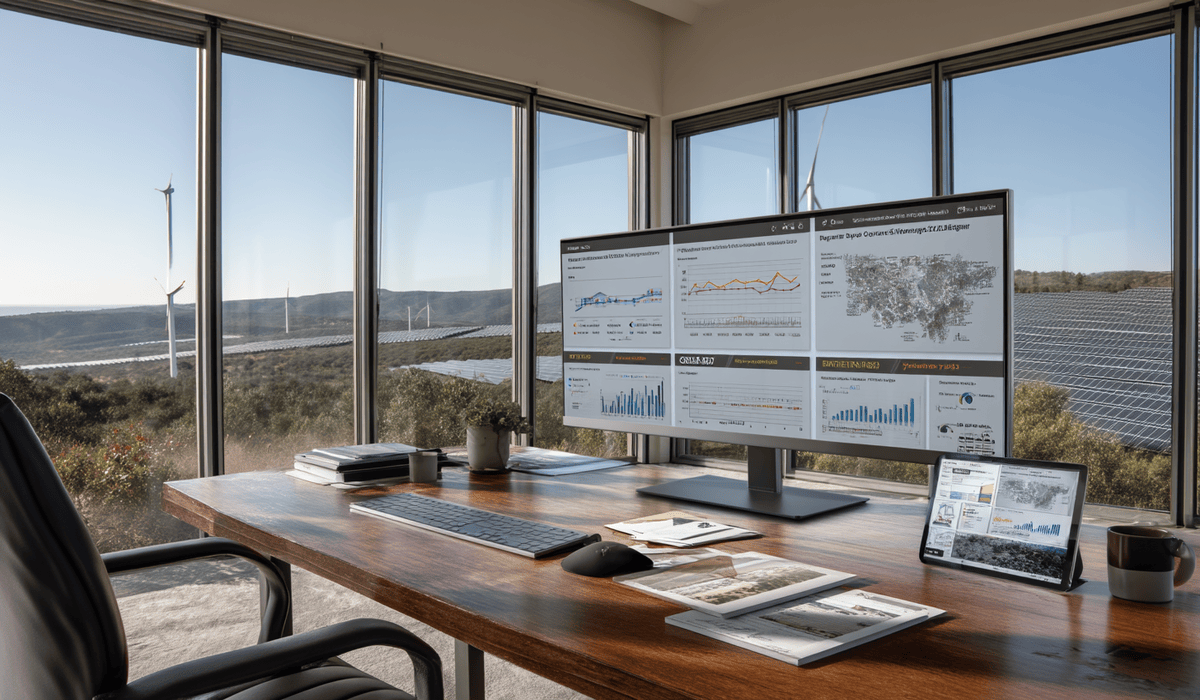

Raw SCADA data only helps if you make something out of it. You want to have clear KPIs on dashboards , availability, specific yield, performance ratio, clipping and soiling loss. Different users require different views. An operator requires alarms and status. A trend and comparisons is what an asset manager needs.

Over the years, you can measure deterioration and compare one pv plant to another in similar weather. I have seen portfolios where a single site was several percent behind and, only by carefully analyzing this approach, was a systematic design glitch apparent.

Investors and lenders expect to find detailed reporting. Clean, traceable data backing PPA obligations and ESG claims. If your monitoring system cannot generate reliable reports it is more difficult to finance new renewable energy projects on good terms.

Interconnecting with Utility, Building and Grid systems

Your SCADA system does not live by itself. It is located within an overall power system. Utilities and ISOs want to see a measurement of telemetry, status, and in some cases need to operate for direct control signals for curtailment or frequency support, in real time.

On the C&I side, the integration with building management systems is important. I worked with a facility that had some SCADA information that was plugged into the building’s controls to allow the plant to “pre-cool” the spaces before peak pricing time, and to allow solar power to pick up a larger share of the afternoon load.

The fact is, interoperability can hurt. Mixed systems of equipment fleets, proprietary protocols and closed APIs cause delay in projects. When planning scada architecture, advocate for open standards and documentation. It saves you from being in a position of being locked to a single vendor for every change in the future.

Designing and Specifying SCADA and Smart Controls for your Project

The best time to think about SCADA is during the beginning time, not when the gear is ordered. Involve your operational people in the design phase. Ask them what they need to see, need to control and what reports matter.

A good spec” is a list of required signals and communications standards, cybersecurity requirements and performance objectives such as refresh rates and historian retention.

Budgeting should take a look at total life cost. I have worked with a project where a small investment in the SCADA’s budget paid for itself in less than two years in terms of reduced downtime and less site visits.

Do not forget testing. Factory and site acceptance tests and operator training are often factors that determine whether or not people actually trust and use the system.

Working with a Turnkey Commercial Solar Installer

The experience your installer has with SCADA can make or break performance. You’d like to get a team with integrated inverters, trackers, meters and utility interfaces on projects that are similar to yours. Ask examples of where they sorted grid compliance type problems with better logic rather than additional hardware.

A strong turnkey commercial solar installer should own the full scope: design, integration, testing, training, and handover. If one group is responsible for both the solar power plant and SCADA, the commissioning process typically goes smoother. I have seen the opposite also, where three vendors had an argument while the owner was waiting for revenue.

Look for long-term support, interesting upgrade paths, and frank discussions on limitations. Be suspicious of partners who are designing controls after reading the requirements.

Future Trends SCADA and Smart Controls Comic Solar

The smart grid is becoming more demanding. Curtailment episodes are more common and grid operators expect to be able to respond faster and more accurately. That puts more intelligence into the plant level power plant controller logic and even at the level of each inverter.

The work of the Electric Power Research Institute on distributed energy resources and the smart grid explains how advanced plant controllers and DER management systems have become critical in helping coordinate the services of solar, storage, and the grid. EPRI points out that these smart control platforms will be required to handle fast-acting grid support functions such as voltage regulation and frequency response more and more as penetration of renewables increases.

We are also seeing an upswing in hybrid configurations, with local control for safety and cloud platforms for sophistication in analytics and energy management. There is some debate about data ownership and privacy and I think that will keep evolving.

Grid codes are continuously changing and this is particularly the case with regards to reactive power, fault ride-through and power quality. The older plants may require control upgrades simply to stay compliant.

If you are planning new projects at this time, plan with flexibility so that you can adapt, rather than build new.

Practical Components for Upgrading Your Current Solar SCADA and Controls

If you already have a SCADA system then begin with a quick health check. Are alarms meaningful or does your operator ignore half of the alarms? Do dashboards demonstrate priorities, or do they simply display a bunch of raw numbers everywhere?

Tidying up lists of alarms together with better priorities and fixing slow communication links often helps to deliver fast wins. I worked with a site where hundreds of nuisance alarms were taken off. After that if something serious happened, people actually took a reaction.

Sometimes you need a bigger change. If you are trying to add storage, expand the pv plant or grid compliance is a major issue then it may be time for a new controller or architecture.

Build a simple roadmap: what do you fix this quarter, what’s needed next year and where do you want the system to be in 5 years using scada as a real tool for optimization, and not just a viewer.

FAQs

What are the functions of a SCADA system in a solar PV Plant?

It allows your operator to see status, receive alarms and send commands to equipment near instantly. For example they can identify the presence of a tripped feeder, validate a condition and remotely close out a breaker compared to driving to site.

How do smart controls maximise solar energy production for commercial solar energy?

Smart logic is responsive to fast faults, curtailment and weather changes. By keeping more inverters online and catching underperformance a priori, you secure energy that would otherwise be lost.

Do we need SCADA for smaller commercial solar systems?

Not always in the utility grade systems, but some structured monitoring and control help. For companies with demand charges or complicated tariffs, it is almost always worth it in terms of better visibility.”

How much does the scada system system for solar usually cost?

Costs depend on size, communication requirements and reporting requirements. The key is looking at that cost in comparison to the value of avoiding downtime, fewer site visits, and cleaner compliance.

How should I choose a SCADA vendor or turnkey commercial solar installer?

You should look for some real project references, good cybersecurity practices, clear support terms, and whether or not they can make and integrate with your utility and IT environment without any surprises.