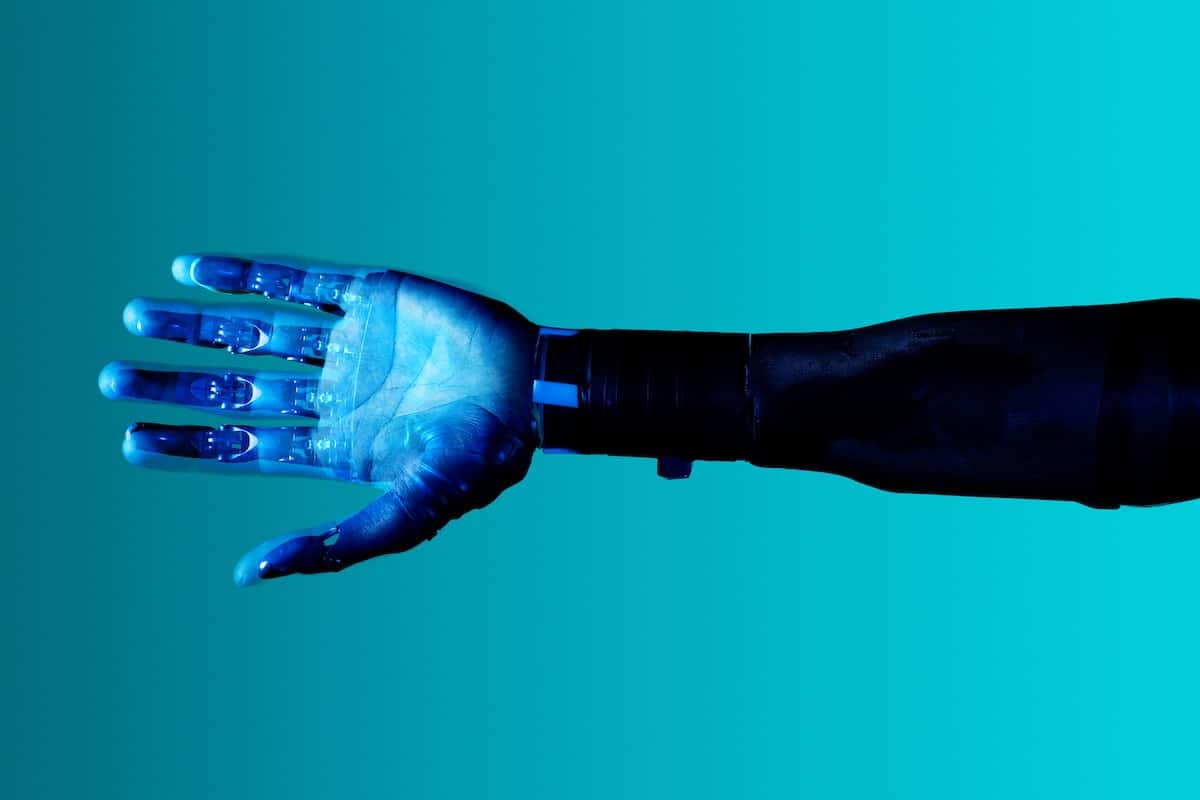

Robotics has revolutionized the way we live and work, and robotic arms have played a crucial role in this transformation. Robotic arms are used in various industries such as manufacturing, healthcare, and agriculture, where they perform repetitive or dangerous tasks with high precision and efficiency. The design of a robotic arm is a complex process that involves several components, including the motors used to power and control the arm’s movement.

There are several types of motors commonly used in robotic arm design, each with its advantages and disadvantages. Let’s explore the most popular types of motors used in robotic arm design:

- Servo motors: Servo motors are commonly used in robotic arm design due to their high precision and accuracy. These motors have a built-in feedback system that allows for continuous control over the position and speed of the arm. Servo motors have a high torque-to-weight ratio, making them suitable for use in lightweight robotic arms. They are also highly reliable and have a long lifespan. However, servo motors can be expensive, and their control systems can be complex.

- Stepper motors: Stepper motors are also popular in robotic arm design due to their precise control over position, speed, and torque. These motors move in small steps, making them ideal for use in multi-axis robotic arms that require precise movement control. Stepper motors do not require feedback sensors, which makes them less complex to control than servo motors. However, stepper motors have a lower torque-to-weight ratio than servo motors and can produce more heat, vibration, and noise.

- DC motors: DC motors are often used in robotic arm design due to their simplicity, low cost, and ability to provide high torque output. These motors are widely available and can be found in various sizes and configurations. DC motors are easy to control and can provide smooth and reliable movement. However, DC motors have limited control over the speed and torque, and their brushes can wear out quickly.

- Brushless DC motors: Brushless DC motors are also used in robotic arm design due to their high efficiency, low noise, and ability to provide high torque output at high speeds. These motors have a longer lifespan than DC motors and do not have brushes, which reduces the wear and tear on the motor. Brushless DC motors can be more expensive than DC motors and require a dedicated controller for control.

The specific type of motor used in a robotic arm design will depend on several factors, such as the payload capacity, the range of motion required, and the desired performance characteristics. When designing a robotic arm, it’s important to consider these factors and choose a motor that can provide the necessary performance and reliability.

In addition to the types of motors mentioned above, linear actuators are also used in robotic arm design. Linear actuators are motors that produce linear motion instead of rotational motion, making them suitable for use in the arms of robotic systems. Linear actuators are simple and lightweight, making them ideal for use in small robotic arms. However, they have limited range of motion and are not suitable for high-speed applications.

In conclusion, the motors used in robotic arm design are critical components that directly affect the performance and reliability of the arm. The most popular types of motors used in robotic arm design include servo motors, stepper motors, DC motors, and brushless DC motors. Each motor type has its advantages and disadvantages, and the specific motor used in a robotic arm design will depend on several factors. When choosing a motor for a robotic arm, it’s essential to consider the arm’s requirements and choose a motor that can provide the necessary performance and reliability.

Doncen Motor is a leading and professional DC motor/ Gear Motor manufacturer that specializes in producing high-quality motors for robotic systems. With years of experience in the industry, Doncen Motor has become a trusted supplier of DC gear motors, offering a wide range of products that are used in various robotic applications. Kindly contact us for best service!!!