Table of Contents

In most bars, taprooms, and restaurants, guests judge the operation by something simple: the beer in the glass. The menu, the lighting, the logo on the tap handle all matter, but a flat, harsh, or “off” pint overshadows everything else. Behind that experience sits an entire chain of CO2 equipment that either supports beer quality or slowly undermines it over time.

From cylinder material to pressure settings and regulator performance, CO2 is not just a utility. It is a critical ingredient that protects flavor, controls carbonation, preserves aroma, and keeps each pour consistent, shift after shift. When that system is engineered well and maintained with care, guests notice it in the first sip, even if they never think about gas at all.

1. CO2 Source Quality Sets the Baseline

The gas itself is the starting point. If the CO2 supply carries impurities or falls short of food grade standards, the beer never tastes as clean as the brewer intended. Contaminants introduce subtle chemical notes, flatten hop aroma, and dull what should be bright, lively carbonation.

This is where reliable CO2 gas cylinder suppliers matter. The better partners focus on purity, consistent filling practices, and tight quality control so bars and breweries receive clean gas that supports shelf life, foam stability, and a fresh, true to style flavor profile in the glass.

2. Cylinder Material Influences Cleanliness and Consistency

Not all cylinders behave the same in real service environments. High quality aluminum cylinders designed specifically for beverage applications bring a few quiet advantages to draft beer operations. They resist corrosion, stay clean internally, and keep the gas supply stable under pressure over long periods.

Aluminum cylinders built with durable alloys stand up to constant handling, transport, and storage in busy back‑of‑house spaces. Less internal corrosion and surface degradation translates into more predictable pressure, fewer leaks, and reduced risk of contamination working its way into the draft system from the gas side.

3. Pressure Control Shapes Carbonation and Mouthfeel

Even the best gas supply falls short if the pressure is off. CO2 pressure directly sets the carbonation level, which in turn affects taste, mouthfeel, and aroma release. Too little pressure lets CO2 escape from the beer, leading to flat, lifeless pours that feel thin on the palate. Too much pressure creates harsh, aggressive carbonation and unstable foam.

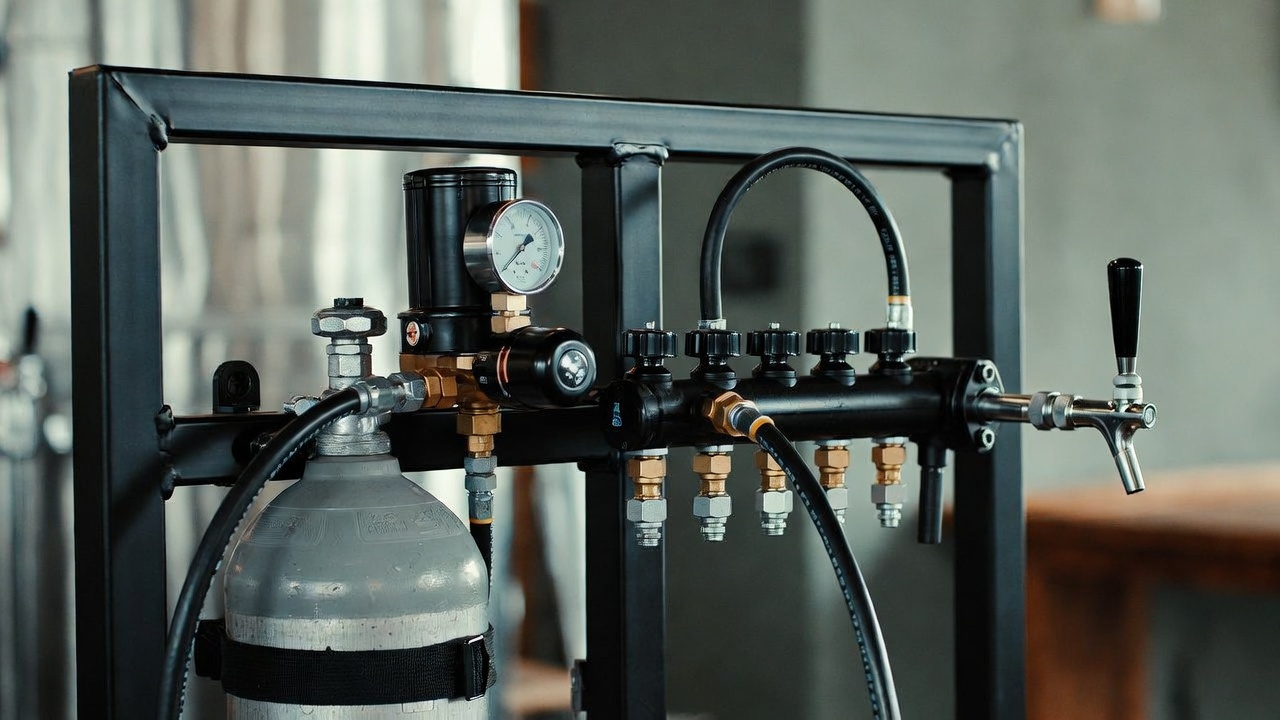

When regulators, valves, and gauges match the cylinder and system design, staff dial in carbonation levels that suit each style, from crisp lagers to hop‑forward IPAs. Stable pressure keeps the bubbles in solution, protecting the balance between sweetness, bitterness, and aroma that the brewer worked hard to achieve.

4. Foam Quality Starts with Gas Balance

Guests often react to foam before they notice anything else. A towering head that collapses instantly or a thin ring that barely clings to the glass both signal trouble. CO2 equipment plays a central role in getting foam right. Excessive pressure, temperature swings, or poorly balanced lines shove gas out of solution too fast, creating big bubbles and a gassy, undercarbonated taste.

A well matched cylinder, regulator, and line setup produces tight, creamy foam that supports aroma and protects the beer surface as the guest drinks. That fine texture feels better on the tongue and carries flavor more evenly from first sip to last, especially in styles that rely on a structured head to show at their best.

5. Temperature, CO2, and Flavor Work Together

Beer does not live in isolation from CO2. Temperature, pressure, and gas all work as a single system. When storage or serving temperatures drift too high, CO2 wants to leave the beer, even if the pressure setting looks right on paper. The result is a pour that tastes dull and flat long before the keg is empty.

High quality CO2 equipment gives staff better control over this balance. Stable cylinders, accurate regulators, and leak‑free connections make it easier to maintain the recommended pressure for the actual cooler temperature, so beer stays within its ideal carbonation range and pours consistently throughout the keg’s life.

6. Oxygen Management and CO2 Purging Protect Freshness

Oxygen quietly ruins beer. It accelerates staling, mutes hops, and introduces cardboard‑like or sherry‑like notes that show up faster than most operators expect. CO2 is the main tool for pushing oxygen out of tanks, kegs, and lines before beer touches them. Effective purging means less oxygen exposure and a longer window of peak flavor.

When CO2 supply is reliable and equipment runs efficiently, teams purge lines and vessels thoroughly before transfers or service. That habit protects freshness, especially in operations that handle frequent keg changes or package a lot of product. Over time, disciplined use of CO2 for purging separates venues that serve lively beer from those where every pint tastes a little tired.

7. Cylinder Design Affects Safety and Downtime

Behind the bar or in a brewery cellar, safety and uptime go hand in hand. CO2 cylinders operate under high pressure. Poorly designed or aging cylinders increase the risk of leaks, valve failures, or more serious incidents that disrupt service and put staff at risk.

Cylinders engineered and tested to rigorous standards, including the right alloys and manufacturing controls, support safer daily operations. Thoughtful design details like clean threads, robust necks, and stable bases, help staff swap cylinders quickly and confidently, reducing downtime and preventing accidental damage to regulators and hoses that could compromise beer quality mid‑service.

8. Durability Helps Beer Quality Stay Consistent Over Time

Draft systems rarely live gentle lives. Cylinders move through delivery trucks, storage rooms, and cramped keg coolers every week. Over years, that physical stress breaks down weaker cylinders and introduces small defects that show up as leaks, pressure fluctuations, or unexpected refills. All of those issues ripple outward and disrupt beer quality.

Durable CO2 cylinders built with strong, corrosion resistant materials handle that abuse with far fewer surprises. Consistent performance means fewer emergency calls, fewer last‑minute cylinder swaps in the middle of a rush, and fewer mystery issues where beer suddenly starts pouring differently for no obvious reason.

9. Visual Condition and Cleanliness Matter More Than They Look

Guests rarely see CO2 cylinders, but staff do. Equipment that looks clean, well maintained, and professional sets a tone behind the scenes. Cylinders with intact finishes, legible markings, and smooth, corrosion free surfaces are easier to inspect, track, and trust.

Over time, that visual clarity supports better routines: staff notice small problems earlier, follow inspection dates more reliably, and handle equipment with more care. Those habits reduce the chances of unplanned gas outages or contamination issues that show up later as inconsistent pours or strange background flavors in the beer.

10. The Right CO2 Partner Simplifies Life for Brewers and Bar Managers

All of this comes down to one practical reality: the people running bars and breweries already juggle enough variables. They manage staff, inventory, menus, and events. They answer guest complaints and solve equipment problems in real time. CO2 should not add to that stress.

Choosing CO2 gas cylinder suppliers that focus on high performance beverage cylinders, reliable production, and consistent quality control turns gas into one of the most predictable parts of the operation. With clean, corrosion resistant, well engineered cylinders arriving on a steady schedule, teams spend less time troubleshooting gas issues and more time refining their beer program and serving guests well.

Bringing It All Together in the Glass

When a guest takes a sip of beer, they notice simple things: Does it taste fresh? Does it have the right amount of fizz? Does the foam look inviting, not messy or weak? Behind those basic impressions sits a chain of equipment decisions that either support or sabotage every pint.

Operators who treat CO2 as an essential part of beer quality, investing in the right cylinders, maintaining solid pressure control, and working with partners who understand beverage demands, see fewer surprises and more compliments. Over time, that quiet consistency becomes part of the bar or brewery’s reputation: a place where the beer just tastes the way it should, every time the tap opens.